Creuset en céramique Leco 528-018. Fabricant de creuset carbone-soufre & creuset cs pour LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker : JW-N009250423 Alpha AR3818 SerCon : SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 AN. Utilisé pour l'analyse élémentaire de l'analyseur de carbone-soufre.

Lire la suite...

Les tubes en aluminium ouverts des deux côtés sont couramment utilisés dans diverses applications industrielles et de laboratoire . Ils sont idéaux pour une utilisation dans des processus tels que le chauffage , le refroidissement et le séchage , et peuvent offrir une isolation thermique et électrique supérieure .

Lire la suite...

Atteignez des niveaux de pureté inégalés avec nos coupelles en cendres osseuses. Conçues pour éliminer les impuretés et les éléments indésirables, ces coupelles vous permettent d'extraire la véritable essence de vos métaux précieux.

Lire la suite...

La feuille de substrat en céramique d' aluminium est un choix idéal pour les applications nécessitant des performances , une fiabilité et une durabilité élevées . Il est disponible en différentes tailles et épaisseurs pour s'adapter à différentes applications .

Lire la suite...

Avantage des tuyaux en alumine: haute résistance à la chaleur, bonne résistance à la chaleur, résistance à la corrosion acide et alcaline. Longue durée de vie. L'OEM est accepté.

Lire la suite...

Un creuset et un bateau lumina sont largement utilisés dans les analyses de laboratoire et industrielles ainsi que dans la fusion d'échantillons de matériaux métalliques et non métalliques. Disponible en différentes tailles et formes.

Lire la suite...

Les tiges en céramique d'alumine circulaire ont un rapport résistance / poids plus élevé que les autres céramiques et peuvent être utilisées pour fabriquer des pièces plus légères et plus solides. Disponibles dans une variété de tailles et de formes.

Lire la suite...

952018.906 Creusets en platine/Pt de 100 μl ( plats d'échantillons) pour TA Instruments TA Q500/Q50/TGA 2950/2050 . Fabricant de creusets TA et coupelles DSC . L'analyseur TA Instruments tga est une bonne alternative pour les gobelets d'échantillon.

Lire la suite...

ME-00024123 Coupelles d'échantillons du creuset en alumine DSC pour les mesures Mettler TGA/robot d'échantillonnage. Fabricant de creusets Mettler Toledo, de bacs à échantillons et de consommables dsc.

Lire la suite...

Grand creuset en céramique de 20 ml 529-047 / 621-331 pour LECO, Alpha AR9047. Fabricant de creuset céramique TGA pour LECO TGA 500/501/601/701, MAC 400 / 500 . Creuset/casseroles en alumine TGA pour analyse TGA-analyseur thermogravimétrique Mesure TGA.

Lire la suite...

Piston plongeur en céramique d'alumine est un substitut idéal pour les pompes métalliques similaires et a été largement utilisé dans les équipements médicaux, l'ingénierie environnementale, le pétrole, la chimie et d'autres industries. Disponible en différentes tailles.

numéro d\'article :

CS-A-3590% 92% 95% 99.5% 99.7% 99%

Material : Alumina ceramic

Shape : OEM

Size : 1-250mm

Alumina ceramic plunger piston advantages:

1. High wear and abrasion resistance

2. Low friction coefficient

3. Increased durability and extended product lifespan

4. Low maintenance requirements

5. Improved sealing capabilities

6. Low porosity

7. Corrosion and chemical resistance

8. Non-magnetic properties

9. Low thermal expansion coefficient

Alumina ceramic plunger piston descriptions:

1. Alumina Ceramic plunger adopts high-performance technical ceramic material, which has high hardness, wear resistance, high temperature resistance and corrosion resistance. Ensure material performance is reliable.

2. The microporous structure obtained by the unique working method of the ceramic plunger working surface has self-lubricating effect, which changes the mechanism of sliding friction and lubrication of the conventional plunger pump.

3. The inner cavity surface adopts a fluid structure with no dead angles or grooves. The surface of the inner cavity is matched with the surface of the plunger by an advanced high-precision internal and external cylindrical grinding machine to the mirror surface, and the outer surface is vibrated and polished to facilitate cleaning and disinfection.

4. The structure of the pump body is finely sealed with the product structure for easy disassembly.

5. These products have been tested for corrosion resistance and acid and alkali resistance, and their indicators have reached the level of international products.

Alumina ceramic plunger piston size details:

OEM: All sizes can be customized and can be made into various complex shapes with high dimensional accuracy. Please clearly provide the height, bottom diameter, top diameter, wall thickness and any special requirements. To speed up the quotation, please provide drawings.

Parameters of Alumina Ceramic:

| Item | Test Condition | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | ||

| Physical properties | Density | g/cm3 | >3.6 | 3.89 | 3.96 | |

| Moisture absorption | % | 0 | 0 | 0 | ||

| Mechanical properties | ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | psiX103 | 20℃ | 358 | 550 | 550 | |

| Compressive strength | psiX103 | 20℃ | 2068(300) | 2600(377) | 2600(377) | |

| Fracture toughness | Mpa.m3/2 | K(l c) | 4.3 | 5.6 | 6 | |

| Thermal properties | Maximum use temperature | ℃ | 1450 | 1600 | 1650 | |

| Thermal expansion coefficient | 1X10-6/℃ | (25-1000℃) | 7.6 | 7.9 | 8.2 | |

| Thermal shock resistance | ℃ | Tc | 250 | 200 | 200 | |

| Thermal conductivity | w/mok | 20℃ | 16 | 30 | 30.4 | |

| Electrical properties | Volume resistivity | Ohm/cm2 | 100℃ | >1013 | >1014 | >1014 |

| Dielectric breakdown strength | KV/mm | 8.7(220) | 8.7(220) | 8.7(220) | ||

| Dielectric constant | (E) | 1MHz25℃ | 9 | 9.7 | 9.7 | |

| Dielectric constant (100MHz) | (E) | 9.5 | ||||

Alumina ceramic plunger piston applications:

1. Alumina ceramic plunger pistons are ideal for applications where high corrosion-resistance and chemical inertness are required. Commonly used in chemical pumps, valves, and other high-pressure applications.

2. They are ideal for applications where high wear-resistance and durability are critical. Commonly used in automotive and industrial engines, as well as in medical and laboratory equipment.

3. Suitable for applications where thermal properties are important. Commonly used in high-temperature applications, such as furnaces and hot water systems.

4. Suitable for applications where chemical compatibility and electrical insulation are necessary. These pistons are often used in electrical components and fuel systems.

5. These pistons are commonly used in aerospace and military applications.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of alumina ceramic plunger piston, such as shape, dimension, quantity, application etc.

Q2. How do I install an alumina ceramic plunger piston?

Installing an alumina ceramic plunger piston requires precision and accuracy. You must carefully measure the hole size, thread pitch, and depth of the hole before installation. It is also important to use the correct type of lubricant to ensure optimal performance.

Q3. What kind of maintenance do alumina ceramic plunger pistons require?

Alumina ceramic plunger pistons should be regularly inspected for wear and tear, and lubrication should be applied as needed. It is also important to check for any signs of corrosion and to clean the piston regularly with a soft cloth or brush.

Q4. What is the lead time for the alumina ceramic plunger piston?

The lead time is dependent on the size and quantity required. Please contact us for more infor.

How to clean alumina ceramic plunger piston:

1. First, wipe the alumina ceramic plunger piston with a damp cloth to remove dust and dirt.

2. Use a soft bristle brush and a mild detergent solution to scrub the alumina ceramic plunger piston.

3. Wash the alumina ceramic plunger piston with clean water, and then dry it with a soft cloth.

4. Ensure that the alumina ceramic plunger piston is dry when used next time.

Quality testing standards:

1. Visually inspect the industrial alumina ceramic plunger piston for any cracks, chips, or other imperfections.

2. Measure the diameter, length, and other critical dimensions of the alumina ceramic plunger piston to ensure that the dimensions are correct.

3. Utilisez un testeur de rugosité de surface pour vérifier toute imperfection de surface.

4. Utilisez un testeur de dureté pour vérifier tout problème de dureté de surface.

5. Vérification du matériau et de la composition chimique du piston plongeur en céramique d'alumine .

Manière d'emballage:

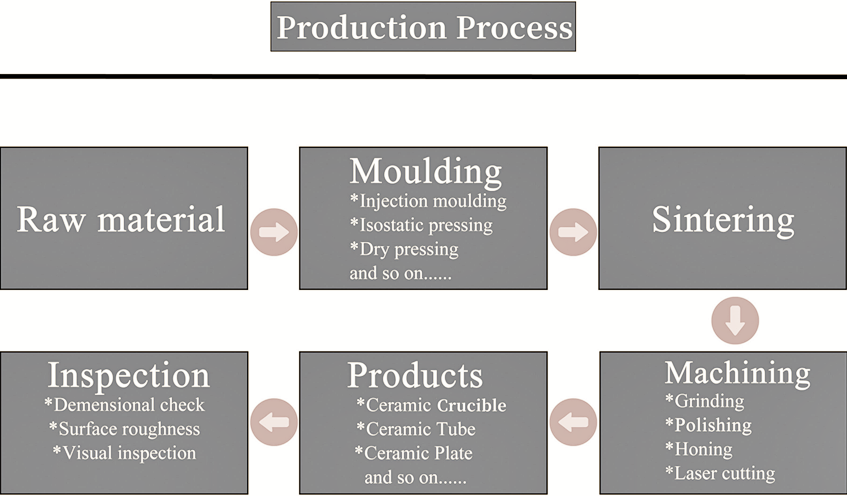

Processus de production:

Pourquoi nous choisir?

1. Nous fournissons des services personnalisés et personnalisés pour répondre à vos besoins personnels.

2. Nous sommes des professionnels expérimentés avec un bon dossier de réussite.

3. Nous fournissons un service client de qualité supérieure et répondons rapidement à toutes les demandes.

4. Nous offrons des prix militants et nous nous efforçons de faire en sorte que vos fonds reçoivent la meilleure valeur.

5. Nous utilisons les dernières technologies et outils pour nous assurer que votre projet est réalisé selon les normes les plus élevées.

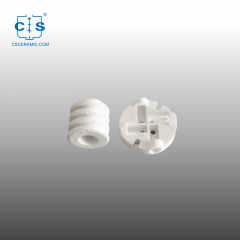

Pièces en céramique de stéatite d'alumine à haute résistance mécanique

Pièces en céramique de stéatite d'alumine à haute résistance mécanique

La céramique de stéatite d' alumine , avec des propriétés chimiques stables, présente d'excellentes performances de résistance à haute température, de bonnes performances de résistance à l'usure et à la corrosion . Fournisseur de composants céramiques.

Tubes isolants de thermocouple en céramique d'alumine

Tubes isolants de thermocouple en céramique d'alumine

Tubes isolants en céramique à haute résistance à l'abrasion et aux chocs, excellente résistance à la corrosion. Fournisseur de composants céramiques.

Isolateur en céramique de douille d'alumine

Isolateur en céramique de douille d'alumine

Isolateur en céramique à douille en alumine pour les terminaisons de câbles.De multiples douilles cannelées et coiffées, des douilles rentrantes, des douilles tubulaires, des douilles cylindriques et cylindriques, etc. peuvent être personnalisées.

Bagues en céramique à roulement à billes en céramique d'alumine

Bagues en céramique à roulement à billes en céramique d'alumine

Le roulement à billes et la bague en céramique d'alumine à haut rendement et légers ont une dureté extrême et une bonne résistance à l'usure, à la chaleur et à la corrosion. Un fournisseur de roulements en céramique pour la Chine.

Pièces de piston en céramique industrielle

Pièces de piston en céramique industrielle

Le piston en céramique adopte la résistance à l'usure ultra-dure des matériaux céramiques d'ingénierie modernes et peut être assemblé par collage de métallisation céramique, soudage, incrustation et technologie de douille.

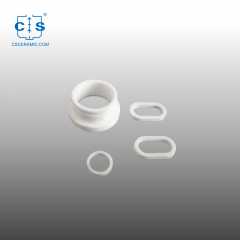

Joint en céramique de rondelle d'étanchéité en céramique à haute teneur en alumine

Joint en céramique de rondelle d'étanchéité en céramique à haute teneur en alumine

Joint céramique rondelle alumine avec une excellente résistance à l'usure, à la chaleur et à la corrosion à haute température. Fournisseur de rondelles isolantes.

95 % à 99 % d'alumine Rondelle en céramique Bague d'étanchéité en céramique

95 % à 99 % d'alumine Rondelle en céramique Bague d'étanchéité en céramique

Al um ina était sa bague d'étanchéité en céramique est utilisée comme joints pour une variété d' applications . Ces anneaux sont conçus pour fournir un joint étanche et fiable qui ne fuira pas ou ne se décomposera pas avec le temps. Toutes les tailles peuvent être personnalisées.

Bague d'étanchéité en céramique d'alumine à haute résistance à l'usure

Bague d'étanchéité en céramique d'alumine à haute résistance à l'usure

Céramique était sa bague d'étanchéité est utilisée comme joints pour une variété d' applications . Ces anneaux sont conçus pour fournir un joint étanche et fiable qui ne fuira pas ou ne se décomposera pas avec le temps. Toutes les tailles peuvent être personnalisées.

l\'équipe professionnelle au service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522